Plastic in Circles reduces plastic pollution in Indonesia

Indonesia consists of 17,000 islands and has the world’s 2nd largest amount of plastic leakage to the ocean. The archipelago generates almost 8 million tons of plastic waste annually. With only ten percent being recycled. The vastness and remoteness of the country mean waste management is fragmented and difficult to realise. Its rivers are dubbed among the dirtiest rivers in the world, but the South Asian country has called in a public-private partnership to rid itself of its waste problem and clean up its reputation – Plastic in Circles (PiCi).

Public Private Partnership Plastic in Circles Indonesia (PiCi)

There are plenty of environmental groups taking action, but litter clear ups mainly focus on the tourism centres that are easy to reach on Java and Bali. Waste management in remoter areas is much more difficult to realise. Here narrow roads and long distances from recycling centres present huge logistic challenges. Systemic changes are needed.

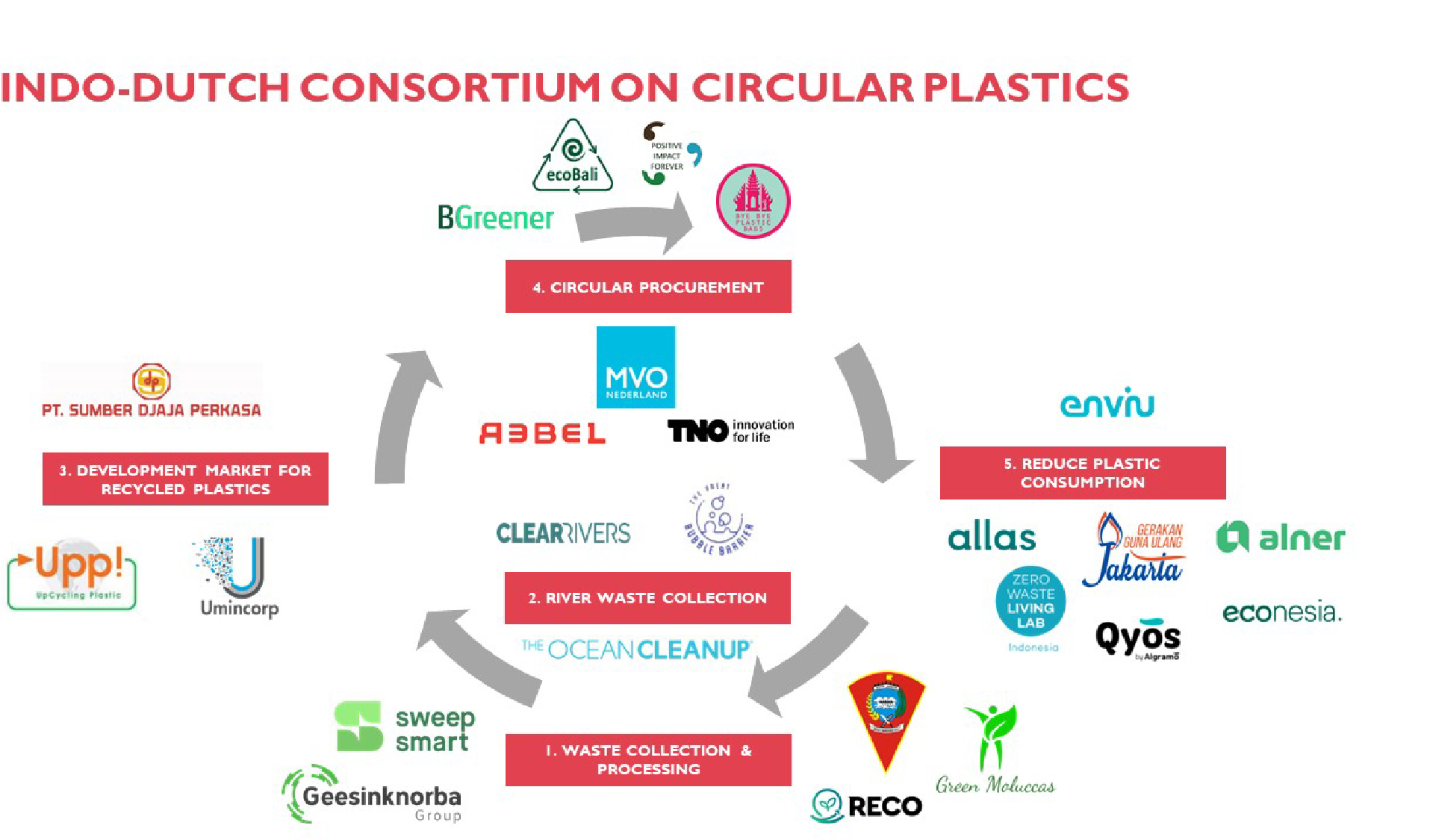

The public-private partnership involving Dutch and Indonesian organisations has set up the PiCi programme to tackle the problem of waste from different angles.

It consists of 5 sub-projects, of which projects 1 and 3 are supported by P4G and the Netherlands Enterprise Agency's Impact Cluster:

1. Waste Collection and Processing

2. River Waste Collection

3. Development Market for Recycles Plastics (in Surabaya, East Java)

4. Circular Procurement

5. Reduce Plastic Consumption

1. Waste collection and sorting on Ambon

Ambon has coral reefs, wooded mountain areas and mangrove forests, but they are heavily polluted with waste. Collection services are unable to negotiate the narrow unpaved roads to collect the 220,000 kgs of waste generated daily. In this region only 2% of it is recycled. Most waste ends up in landfill. And at least 25% (50,000 kg) of the waste leaks into the environment.

PiCi has developed a smart waste centre, using modern equipment to sort 28 types of mixed and dry waste. The aim of the initiative is not only to tackle the issue of waste, it also provides healthy and ergonomic work for its mainly female workforce of 34 workers.

Indonesian partner Green Moluccas is also increasing the quality of waste collection by educating 2500 households in five communities on segregating dry and wet waste at source and arranging segregated collection in the communities. This speeds up the recycling process.

State-of-the-art waste management technology

The smart waste centre uses state-of-the-art Dutch waste management technology and know-how to sort over 10 tons of mixed and dry waste every day, preventing 1,000,000 kg valuable waste ending up in landfill or in the environment every year.

Swift sorting takes place on a Sweepsmart conveyor belt, which makes the process faster and safer. Also a waste collection vehicle and baling machines compress materials for more efficient transport and storage. At the centres, a dashboard tracks waste flows and on the ground collection to improve operational performance.

Ultimately this stops plastic waste from entering the oceans and adding to the global problem of plastic soup. Resource recovery provides an output of high-quality sorted plastics which are ready to use for effective recycling. This makes the centres financially independent enterprises.

2. River Waste Collection

Indonesia has commissioned HZ University of Applied Sciences to monitor water quality. Indonesia is home to 83 of the world’s 1000 worst polluted rivers. Clear Rivers’ litter traps, the Bubble Barrier and The Ocean Cleanup’s Interceptor aim to retrieve waste from Indonesia’s waterways in a bid to tackle river pollution. Strengthening the country’s commitment to prevent plastic waste on its waterways.

3. Recycle 2 Value

In 2022, a Memorandum of Understanding was signed for subproject Recycle 2 Value. The project will establish a Circular Plastic Factory in Surabaya ─ the Upp! factory and is investigating the potential for a Umincorp Magnetic Density Sorting factory in Surabaya.

The Upp! factory will use a unique technique to process unsorted, unwashed and unshredded plastics and convert these into recyclable building materials. A feasibility study has been successfully concluded to assess the application of efficient sorting technology so that the market can be expanded to recycled rigid plastics in Indonesia.

The Recycle 2 Value project will:

- Introduce advanced technologies for better recycling implemented with Indonesian companies

- Further strengthen the recycling infrastructure by enabling new waste streams and generating job opportunities

- Substitute virgin products from fossil-based resources for circularly recycled resources

- Support the transition towards a circular economy, facilitating a system change.

- Create a market for high-quality recycled polymers (PET, Polypropylene, Polystyrene, Polyethylene) for brand owners (ultimately packaging-to-packaging)

This could generate 200 jobs, and save up to 30,000 tons of waste a year from incineration, landfill and leakage into the environment.

4. & 5. Circular Procurement/Reducing plastic consumption

Subproject 4 Circular Procurement aims to introduce circular sourcing in Bali’s tourism industry.

Efforts are also being made by Zero waste living lab - Enviu to reduce plastic consumption in Subproject 5 by creating alternative systems through setting up ventures that provide reuse and refill solutions. This reduces the use of difficult to recycle single use plastic packaging.

Indonesia’s environmental goals

In line with Dutch government aims, the partnership is helping the Indonesian government to achieve its environmental goal to reduce marine plastic by 75% and increase its waste handling to 70% by 2025. It also has the potential to scale up and act as a blueprint for other regions. Its impact will be measured by TNO and Rebel Group using a dynamic web-based tool and TNO’s Plastic Recycling Impact Scenario Model (PRISM) model.

The Netherlands Enterprise Agency's P4G programme has provided this partnership with US $1,046,004 in catalytic grant funding. This public-private initiative is led by MVO Nederland and supported by the Dutch Ministry of Infrastructure and Water Management.

MVO Nederland organised a mission in June 2023 for the PiCi consortium and all relevant stakeholders and visited Ambon, Surabaya and Jakarta. A final mission will be organised in Autumn 2023.

Return to P4G Netherlands.

Read about other P4G NL projects