Biomass India: turning waste into to valuable products

Winter in northern India. A thick blanket of smoke covers the land. This is when farmers burn paddy or rice straw, a by-product of rice cultivation. India, the world’s second-largest producer of rice, is sitting on a mountain of raw material, without realistic options to cash in on it. So each year, farmers burn around 90 million tons of rice straw, releasing a considerable amount of C02 in the process. Under the guidance of NL Works, Indian and Dutch public and private organisations have created the Biomass India consortium to convert this waste into climate-positive products.

A reduction in life expectancy, rising healthcare costs, poorer soil quality: the negative effects of burning rice straw are clear. If farmers could be persuaded to get rid of this unwanted by-product in another way, their overall farm output and productivity would actually benefit. A combination of limited financial resources, machinery and manpower means rice straw is currently barely harvested. By buying the residue rice straw, the Biomass India consortium provides farmers with an incentive not to burn the product, but to sell it. Taking waste to a collection centre becomes worth their while.

From unwanted by-product to high-quality, sustainable products

Biomass India has the ambition to become the leading Indian forum for biomass upcycling, turning agricultural waste into products and services of value for the global market. This innovative Indian-Dutch partnership brings together entrepreneurs, investors, innovators, farmers and policymakers. Together, they work on transforming agricultural waste into resources for the energy, paper and packaging, construction materials, fertilisers and textiles industries. Their aim? To provide India’s rice farmers with additional income, while reducing CO2 emissions and improving air quality.

Rice straw pilot projects

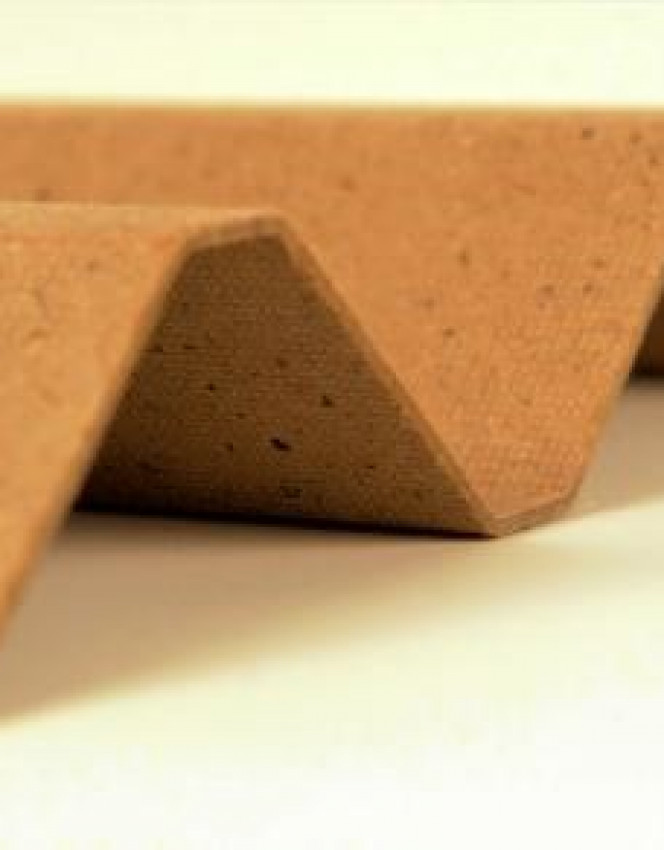

The first pilot projects are well underway. In 2022, a Venlo-based factory received a first batch of 150 tonnes of rice straw, to be turned into furniture panels. If successful, India’s very first rice straw-based factory for construction materials will open its doors later in the year. A second factory is expected to follow suit. Combing Indian and Dutch technologies, the Humankind Group and its Indian partner intend to produce rice straw-based biogas and organic fertiliser. To play into the rising demand for plastic replacements, a new R&D project focuses on processing rice straw using existing machinery.

Dutch circular technologies

As this wide variety of projects shows: rice straw is more than just agricultural waste, it is a product of great versatility. The latest Dutch circular technologies by companies such as Humankind Group, ECOR and many more are deployed to help India transform rice straw into various sustainable products and services.

A new India-based team will spur structural innovation and accelerate the scaling of existing technologies. And as more and more parties join the consortium, options to turn rice straw into valuable products are only expected to increase in the future. Just recently, the Laudes Foundation (former C&A Foundation) and Wageningen University came on board to research the potential application of rice straw-based viscose fibers in the textile industry, for example.

The learnings of this project can serve as a source of inspiration beyond India showing how to make value from agricultural waste. Globally around 700 million tonnes of rice straw is produced annually, of which a significant proportion is burned by farmers. Similarly, much of the wheat straw and cotton stack is burned. Turning this agricultural waste into a valuable resource has the potential to be an important driver towards a more sustainable and circular economy.

Making the circular shift together

No country can make the circular transition alone. In today’s globalised world, where base materials for products often come from all over the world, working together is essential to make the circular shift. One country’s waste can be another country’s resource. Let’s work together to turn today’s social and environmental challenges into tomorrow’s economic opportunities and jobs.

If your private-sector company is interested in contributing to impact programmes on growth markets, please contact NL Works.

Read more: Working on sustainable packaging from rice waste | MVO Nederland