Articles

- (-) Show all

- Agri & food

- Water

- Join us at Expo 2025 Osaka Kansai Japan!

- New Dutch

- Programme Road2Osaka

- Sustainable cities

- Circular economy

- Peace, justice & equality

- Energy transition, sustainability & circular economy

- Green cities

- Horticulture

- Life sciences and health

- Maritime

- Sport

- Startups and scale-ups

- 2025 年大阪・関西万博でお会いしましょう

- Creative industries

- Digitalisation

- High-tech systems and materials (HTSM)

- Road2Osaka 大阪万博に向けた取り組み

- Water, energy & food

- Climate policy

- Culture

- Sustainable and smart mobility

- Human rights

- P4G Netherlands

- Earth

- Food

- Hydrogen

- LGBTIQ+

- Life sciences, health & sport

- Offshore wind

- Creative Industries

- High-tech and digitalisation

- Communities

- Health

- Rule of law

- Tech

- Emergency aid and humanitarian diplomacy

- International The Hague

- Security

- The Netherlands in Perspective

- World Press Freedom

-

Beyond the breakthrough: how digital convergence is shaping 2026

-

Shaping the future of cancer care in Utrecht

-

Waterproof: Global stories of water resilience

-

Building resilient cities from the ground

-

Transforming pharmaceuticals with Organ-on-a-Chip technology

-

Field report: feeding Colombia's cities

-

NLwatertech2Italy workshop: emerging contaminants

-

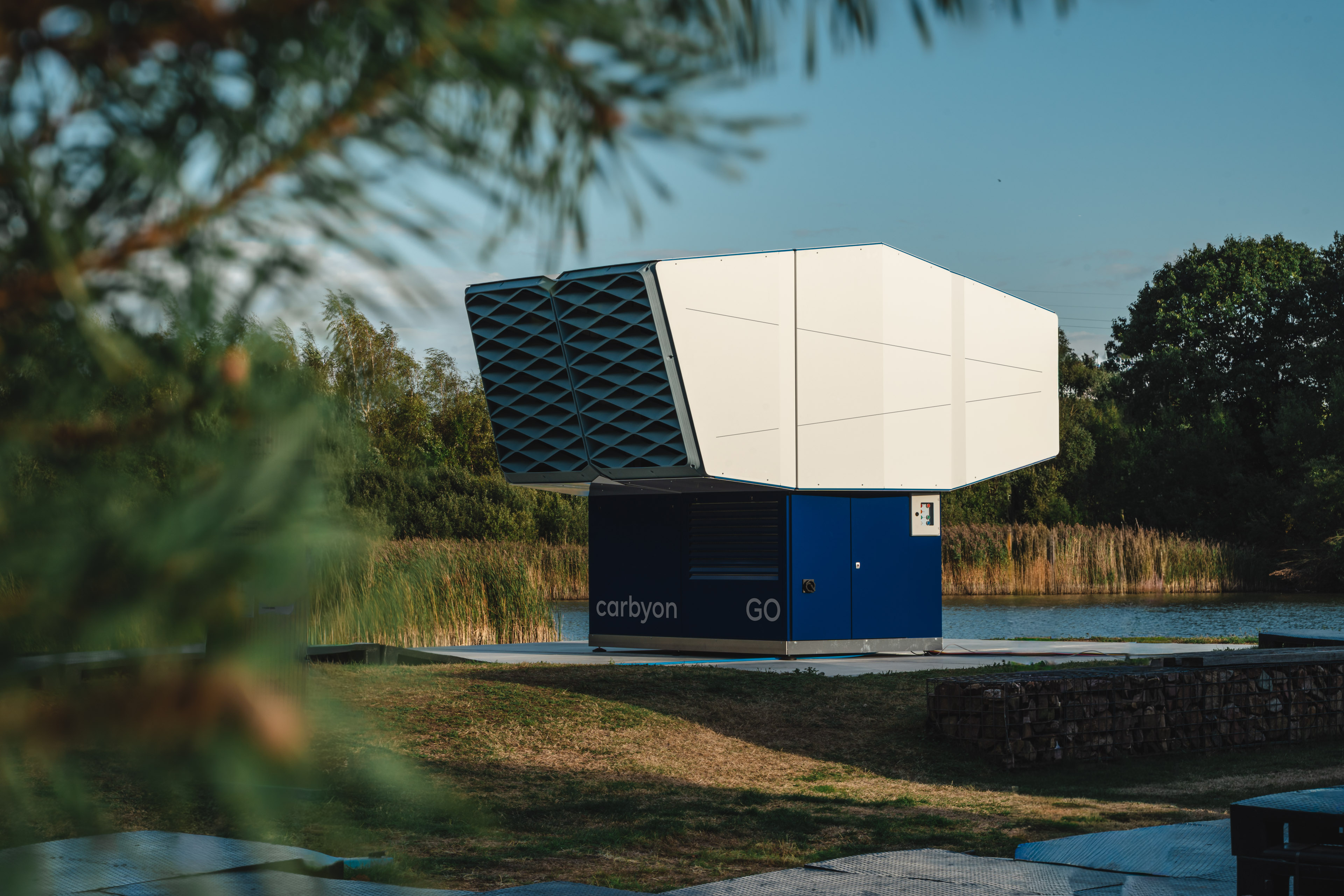

What if we could vacuum the sky?

-

From clay to concept, we’re printing the future

-

Celebrating a decade of the Dutch Startup Visa

-

Rising stay rates among international graduates: a boost for the economy

-

Measuring the gravity of the universe in Maastricht

-

Singapore's first polder

-

Harnessing Dutch innovation to boost Philippine farming

-

A destination full of discovery

-

Meet the most innovative students of the Netherlands

-

Let’s close the loop on the textile industry

-

Strengthening ties through water

-

The Netherlands and Mexico working together

-

The Netherlands and Thailand working together

-

How partnerships in energy shape a sustainable future